Delivery time door-to-door : ~ 3 months.

Nickel-Iron batteries are an excellent choice for remote locations where reliability and longevity are the primary factors. These batteries do not suffer from the degradation effects commonly seen in lead-acid batteries (electrolyte stratification, sulfation, electrolyte deterioration, electrode corrosion leading to internal short circuits), even in the best versions (OPZ). The average lifespan of a Nickel-Iron battery is over 20 years under normal use, with the added benefit that its electrolyte can be replaced to rejuvenate its performance. Nickel-Iron batteries have over a century of proven performance, and their behavior in the field has been extensively studied and documented in specialized literature.

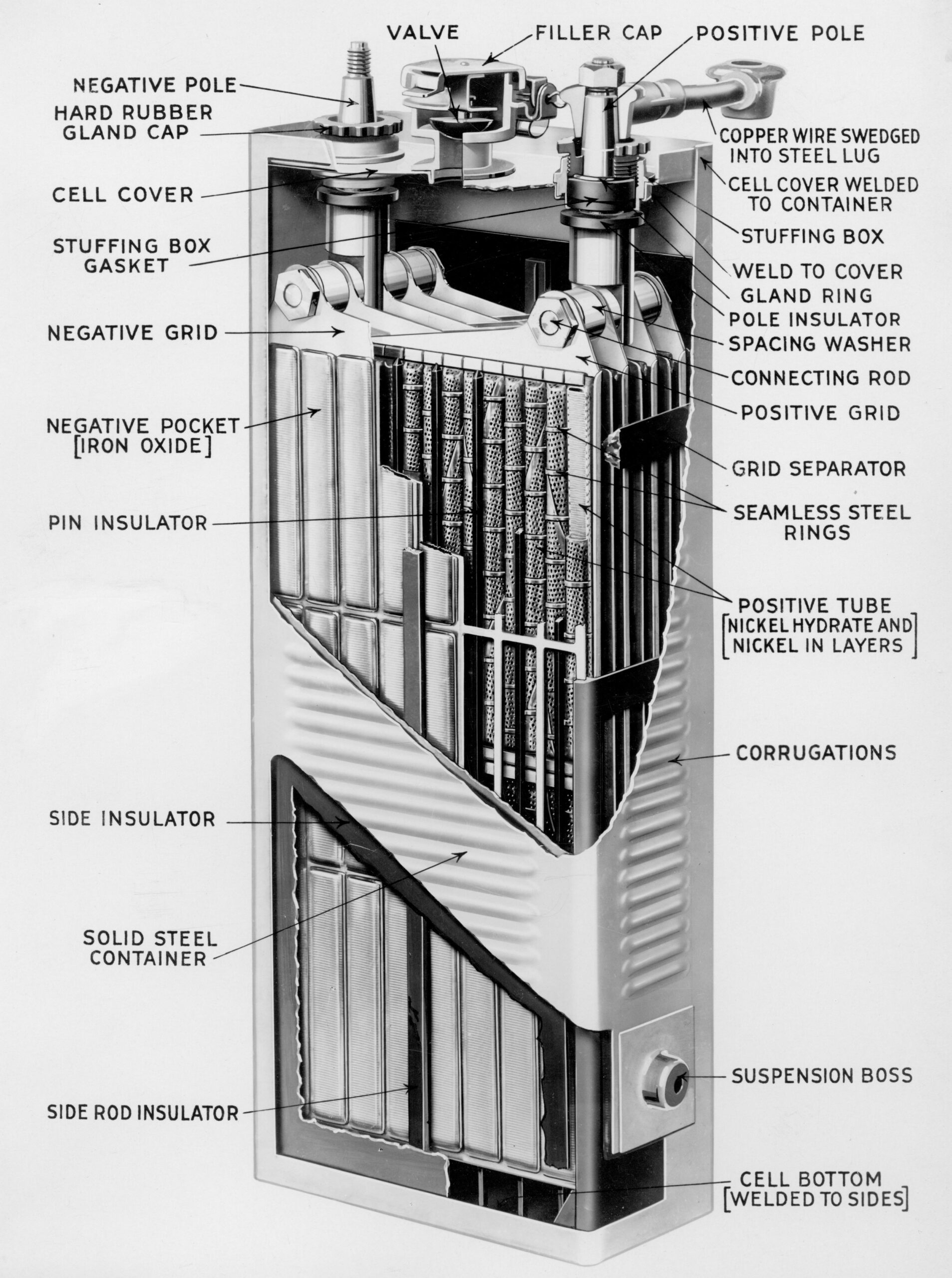

Original Thomas Edison Nickel-Iron design (from the patent)

Edison once claimed that his batteries were designed to last a century. While Edison, being a brilliant businessman, certainly knew how to craft a compelling sales pitch, there is documented evidence of a 1934 batch of Nickel-Iron batteries where 50% of the capacity was recovered (link).

Although they are more expensive upfront compared to the best lead-acid batteries, this is justified by the cost of raw materials (Nickel), and the investment is offset by a low total cost of ownership.

Their high tolerance to abuse (prolonged partial charge, short-circuiting, extended deep discharges, mechanical shocks, freezing) provides great peace of mind, making them particularly well-suited for the harsh conditions often encountered in off-grid setups.

An old, reconditionned set of Nickel-Iron cells manufactured in 1950

Below, one of our customers with our Nickel-Iron batteries :

Unmatched in robustness and longevity since their invention in 1901 by Thomas Edison and W. Jungner, Nickel-Iron batteries fell out of favor in the 1970s, overtaken by the more affordable lead-acid batteries, and later by lithium-ion in the 1990s. The exceptional longevity of Nickel-Iron batteries is explained by their chemical properties (see PDF study).

The structural degradation of the components (iron electrode and nickel electrode) is virtually non-existent, thanks to an alkaline electrolyte that acts as a preservative for the metals, much like in Nickel-Cadmium batteries (as opposed to acidic batteries). Historically, they were used in challenging conditions such as subways, mines, and military aviation.

Nickel-Iron batteries use a non-flammable alkaline electrolyte, with no flash point, composed of an aqueous solution with approximately 25% potassium hydroxide (KOH).

Free from environmental toxicity and without harmful gas emissions, these batteries do not require electronic management systems (BMS), unlike lithium batteries, where the organic electrolyte does not provide a regulatory function in case of overcharging.

The electrolyte can be replaced by the user, using technical-grade potassium hydroxide powder and distilled or ionized water. The trade-off for this safety-oriented design is that Nickel-Iron batteries have a lower efficiency (~80%) compared to lithium batteries (>95%).

The tubular design of the battery, where the electrode materials are enclosed in finely perforated, nickel-plated tubes, provides very high mechanical resistance (to shocks).

This is precisely why Edison initially designed these batteries to be used in automobiles.

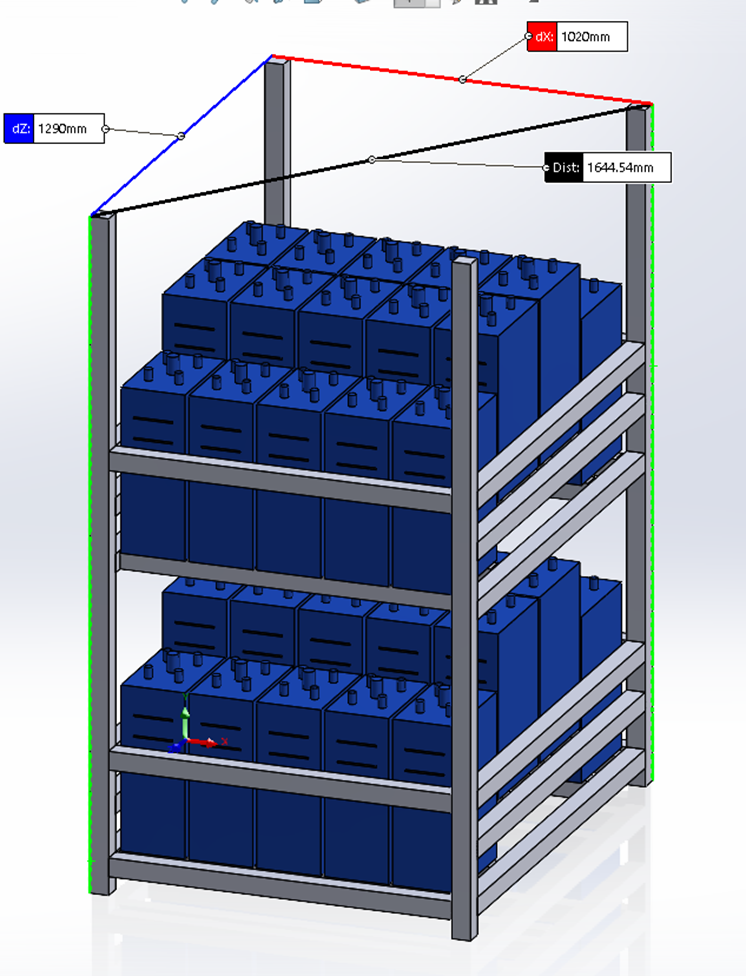

Customized rack that allows a smaller footprint and yet a 20 kWh storage capacity in 48V !

| Capacity (Ah) | 200 Ah, 300 Ah, 300 Ah, 400 Ah, 500 Ah, 600 Ah, 700 Ah, 800 Ah, 900 Ah, 1000 Ah, 1100 Ah, 1200 Ah, 1300 Ah |

|---|

PERMA BATTERIES, LLC – EIN # : 612193761 – 131 Continental Dr, Suite 305 Newark, DE 19713 USA