✅ 5.12 kWh capacity / 48V

✅ Rackmount 3U form factor

✅ Scalable up to 80 kWh per string

✅ Dynamic BMS with closed-loop comms

✅ Compatible with top inverter brands

✅ Certified safe (UL, CE, UN38.3)

✅ Made for solar, off-grid, telecom…

The AES RACKMOUNT 48-48-5120 from Discover Energy Systems is a state-of-the-art, rack-mounted lithium battery designed for high-performance, professional energy storage applications. If you’re searching for a reliable, intelligent, and scalable lithium solution, the AES RACKMOUNT system is the gold standard for residential, commercial, and industrial installations.

Documentation and certificates are available on DISCOVER ENERGY’s website :

You can check David Poz’s full breakdown of the Discover AES battery in the video below :

At the heart of the AES RACKMOUNT 48-48-5120 is Discover’s award-winning AES LiFePO₄ chemistry. Engineered for efficiency, this lithium iron phosphate battery delivers outstanding cycle life, rapid charge/discharge capability, and long-term reliability. With a 5.12 kWh energy capacity and a 48V nominal voltage, it is perfectly suited for both on-grid and off-grid solar power systems.

The AES RACKMOUNT battery integrates seamlessly into existing power infrastructures, providing a dependable backbone for critical power needs, peak shaving, or time-of-use optimization.

Discover’s AES RACKMOUNT battery line features a proprietary High-Current Battery Management System (BMS), offering dynamic protection, real-time diagnostics, and performance optimization. The BMS ensures:

Active cell balancing

Temperature and voltage monitoring

Remote diagnostics and control

Multi-layered safety protocols

Thanks to integrated closed-loop communication protocols with leading inverter brands (Victron, Schneider, Sol-Ark, OutBack, and more), the AES RACKMOUNT battery guarantees full system compatibility and plug-and-play operation.

In modern energy storage setups, the term “closed loop” refers to the two-way digital communication between key system components—such as batteries and inverter-chargers—even when sourced from different manufacturers.

Within a battery energy storage system (BESS), the battery management system (BMS) sends real-time information—such as state of charge (SOC), voltage, current, and cell temperature—to the inverter-charger. This information also includes dynamic requests for specific charging voltages and currents. Based on this feedback, the inverter-charger adjusts its operation accordingly, effectively completing a feedback loop that ensures safe and efficient charging.

In contrast, an “open-loop” configuration does not include this data exchange. Instead, charging parameters must be manually input into the inverter-charger. Additional external devices—like temperature sensors or battery monitors—may be needed to approximate conditions such as SOC or temperature, but they do not allow for direct interaction between the BMS and inverter.

1. Enhanced Safety

Closed-loop systems allow the BMS in the Discover’s AES Rackmount to directly influence charging and discharging by initiating protective actions—like stopping the process in case of high temperature, excessive voltage, or overcurrent.

2. Simplified Setup

Because the BMS can automatically transmit configuration data, there’s minimal need for manual input, making the installation and setup process much more user-friendly.

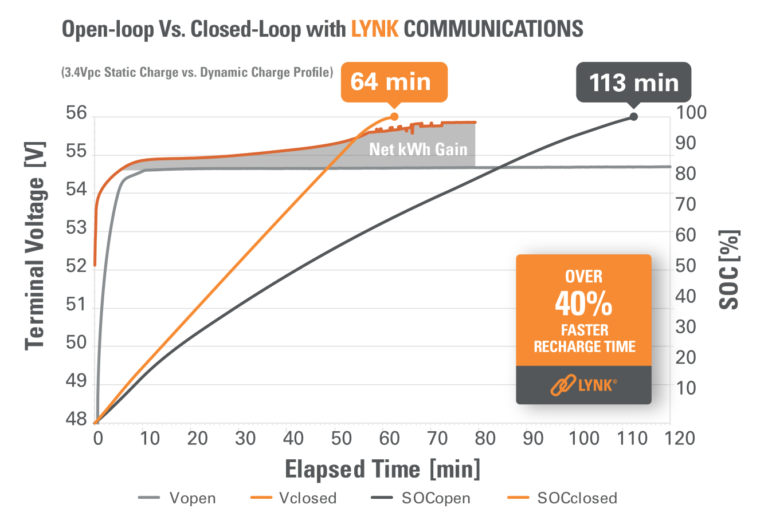

3. Accelerated Charging

Dynamic communication allows the BMS to request optimized voltage and current levels, enabling charging speeds up to 25–40% faster than traditional open-loop configurations.

4. Improved Monitoring

Closed-loop systems allow inverter-chargers to display accurate battery data—such as SOC and temperature—straight from the BMS, improving system visibility and management.

A well-designed BMS plays a central role in system protection. It typically halts charging or discharging in response to unsafe conditions like high/low temperatures or voltages. In a closed-loop setup, once the condition resolves, the BMS can also automatically resume operation—without user intervention.

Take cold-weather charging, for instance: lithium batteries are particularly vulnerable below freezing. A BMS will stop charging below 0 °C and only allow it to resume once the temperature returns to a safe level. Some advanced batteries incorporate internal heating or strict low-temperature logic to ensure optimal operation in colder climates.

Closed-loop systems also greatly reduce the burden of manual configuration. The BMS communicates charging parameters directly to compatible inverter-chargers using standardized communication protocols—often via robust and reliable CAN bus over CAT5 or similar cabling.

However, because signal wiring (e.g., CAN High, CAN Low, Ground) varies between brands, correct wiring and cable preparation are essential. Installers must refer to the inverter’s technical documentation and may need to set master-slave configurations when using multiple batteries in parallel.

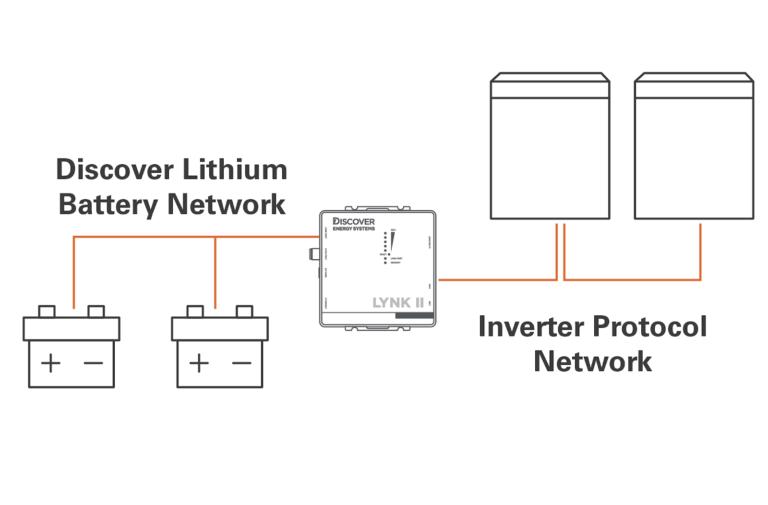

A practical solution for these challenges is the LYNK II Communication Gateway, which bridges communication between Discover AES Rackmount battery batteries and supported inverter-chargers. It simplifies integration by eliminating the need for crossover cables and automatically managing battery network communications.

Some systems go further by enabling dynamic charging, where the BMS continuously sends optimal, real-time voltage and current targets. This approach shortens charging time and minimizes energy losses from cable resistance.

Dynamic systems also excel at cell balancing—a process that evens out charge across all cells in the battery. The BMS slightly raises voltage at the end of the charge cycle while reducing current, allowing higher-voltage cells to finish charging safely.

| Version | 48-48-5120, 48-48-5120-H (heated) |

|---|

Reviews

There are no reviews yet.